Another View of Newport

By Helena Touhey

Newport Craft expands with a focus on production, community, hospitality, and innovation

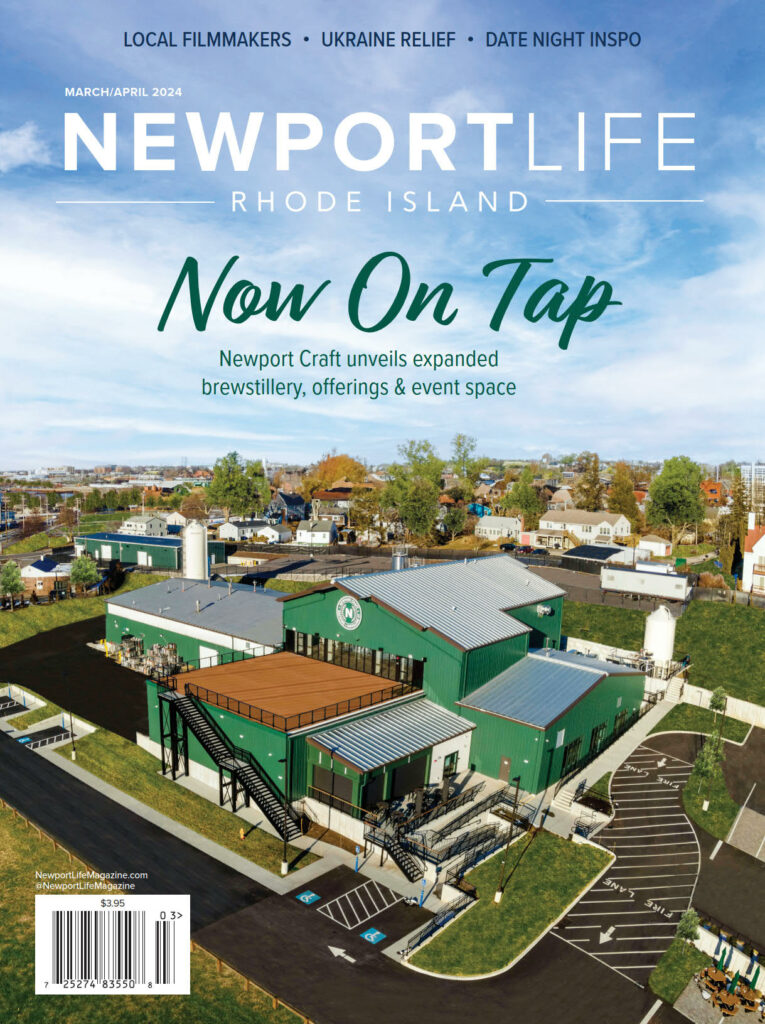

It’s no secret a transformation has been underway at Newport Craft. This spring, after a four-and-a-half-year multiphase project, the brewery and distillery — “brewstillery” — in the city’s North End will publicly re-open its doors to the thirsty, the curious, and the celebratory. Visitors will find an expanded footprint both inside and out, one that is more innovative and efficient as well as able to host gatherings and events.

“We want this to be a blank canvas for the community,” says Brendan O’Donnell, who oversaw the project — which continued without interruption to production, even during the pandemic — and serves as Chief Executive Officer of Newport Craft Brewing & Distilling.

For him, the role of hospitality was central in shaping the design of the space and its intended uses, which he envisions including community markets, film events, and music gatherings, which will add to ongoing efforts to revitalize the North End.

One of the most striking new features is the addition of a second floor, where an event space extends into a large outdoor deck offering panoramic views of the Newport Bridge.

“This is the gem,” says O’Donnell, “the view is so crazy.” It looks out towards Newport Harbor, where the bridge stretches across the horizon, equally as impressive on days with mercurial cloudscapes as on nights with majestic sunsets.

The second floor also features an indoor bar and large kitchen space, which can be used for event catering or chef popups; eventually, it could even be used by local cooks in need of a certified kitchen. The main room has been designed with music in mind and a variety of events are planned for the space; it recently hosted the 21st annual Newport Wedding Show, where numerous booths were set up and for which nearly 700 people passed through.

Outside on the lawn (famously known as the festival fields where Bob Dylan went electric), come summer, there will be a tent for other events and another bar styled from a shipping container. A third bar sits to the left of the main entrance, which is just off the expanded parking lot, where guests can saddle up for a tasting after taking a tour of the brewhouse and distilling room or simply hangout with friends on a weekend afternoon.

“It’s another view of Newport,” says O’Donnell, referring both to the literal view, and his vision for Newport Craft and its role within the greater community. “Our goal is to be able to say yes as much as possible.”

A new brewhouse, an age-old process

Hops, malt, yeast and water. These are the essential raw ingredients used to make beer, which is essentially a process of fermentation, one where yeast eats sugar and makes alcohol.

The new brewhouse will allow for this age-old practice to continue in more efficient ways with an increased capacity, streamlining the process of making beer into an eight-hour window and reducing wasteful byproducts. With the expansion, Newport Craft is now one of the top 50 largest brewing and distilling operations in the country, and has the capacity for brewing 100,000 barrels of beer a year. As for distilling, work is underway to increase the library to 10,000 barrels over the next couple of years.

Newport Craft is considered a regional brewery because of its size, and products are distributed in nine states, mainly throughout New York, New Jersey, Massachusetts and Rhode Island.

Several components of the project have made the brewery a more innovative and environmentally focused operation. A major undertaking involved installing a new groundwater runoff design and a new waste-water treatment system, which uses enzymes to break down sludge and solids, along with caustic and acid to neutralize the pH levels. This will, everyone on site is quick to note, return water to the city cleaner than it arrived.

Grain leftover in the brewing process is called spent grain. At Newport Craft, it fills one of the smaller silos and is available for any farmer to come and collect — free of charge — to reuse as animal feed. It’s especially good for pigs and cattle.

O’Donnell has plans to use some of this spent grain to make dog treats — which he sees as a win-win not only because they are nutritious, but also because it further keeps this waste from entering the water stream.

Another new product will be a line of canned waters, called Clear Harbor, which are far more recyclable than single use plastic bottles, and which furthers Newport Craft’s sustainability initiatives.

Wild ales and quality control

Within the cavernous brewhouse is a side-room that will exist as its own ecosystem, one used for making wild ales, also known as sours, which will be bottled not canned.

“It’s the prettiest room in the brewery,” says Scott Douglas, the General Manager, who’s been with Newport Craft since 2020. Within this room are two large wooden barrels known as foeders, their texture in contrast to the stainless-steel tanks in the main brewhouse.

It’s important to keep the bacteria used for making wild ales separate from the bacteria used to make everyday beers. The key bacteria strains for souring beer are lactobacillus, pediococcus, and brettanomyces. (Douglas and his colleague Brian Combes were asked on the spot if they could name — and spell — the bacteria strains used in this room, and they did not disappoint; such factoids are among the tidbits to be gleaned on a tour of the brewery).

“This is a blend of bacteria that sours and funkies beer,” explains Combes, who oversees the brewhouse production floor; he’s been at Newport Craft since 2021. Once bottled, the sour and wild ales will continue to ferment.

The staff will be undergoing sensory training, which is a way to “develop each other’s palates,” says Combes, not just in the sense of what individuals prefer, but in the sense of how one develops a palate — and brews a beer that is consistently palatable. Of note, he adds, is that the brewery will soon be able to grow its own in-house yeast strains.

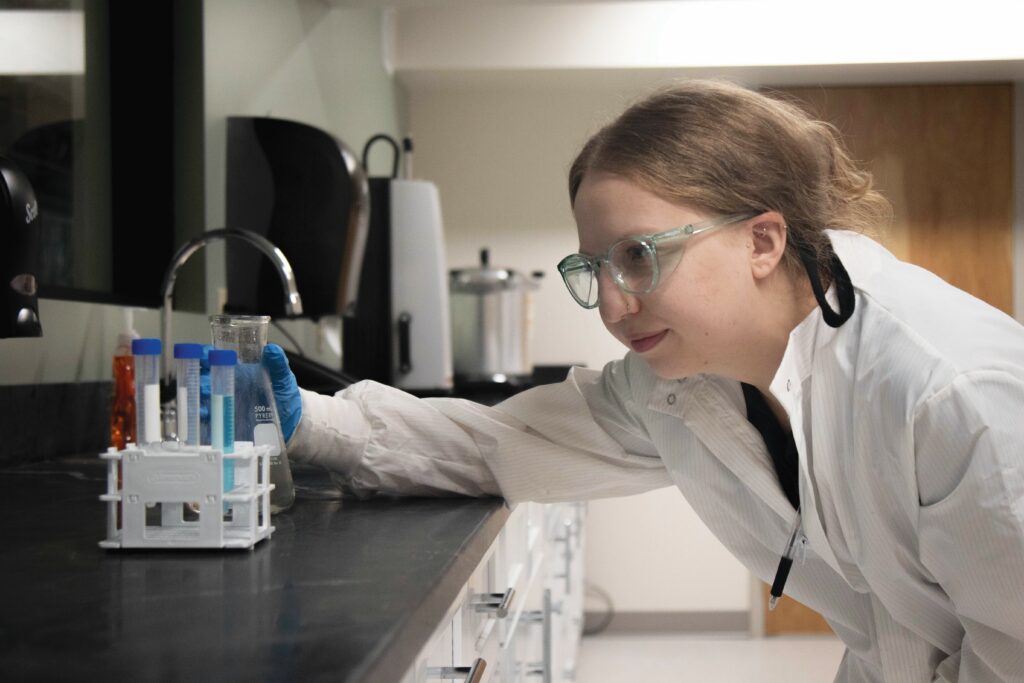

That venture is connected to another new feature of the brewery: a microbiology lab, overseen by Lydia Jenkins, brewery lab tech. Jenkins came to Newport Craft from the world of cannabis and before that was a culinary student at Johnson and Wales University in Providence. She describes working in a brewhouse lab as “really awesome,” and noted Newport Craft is the only brewery in the state to have such a lab on site.

“You can identify any problem right away,” she said, “instead of having to wait.”

At Newport Craft, the beer is tested at five different points from the brewhouse to package. Among the things being tested are carbonation and oxygenation, as well as good yeast versus bad yeast.

“We’re really able to control the quality of our products,” says O’Donnell of the regular onsite testing.

Jenkins’ arrival in February also increased the number of women working in the brewhouse. She joined Holly Timson, who started at Newport Craft in November; Timson left a career in interior design to become a brewer, learning quickly (her prior experience, she said with a grin, was that of drinking beer), and easily holds her own among the men.

“Me and Holly love it,” says Jenkins of their work. “It’s nice to have other women in a male dominated industry.”

The distilling of spirits

On the far side of the brewery, near the parking lot and the field, is another silo, this one exclusively for distilling. While the brewing operation takes up the largest section of the production space, followed by the canning, packaging and shipment area, the distillery portion of the “brewstillery” is tucked into a sunlit space with a similar but distinct operation: that of making liquor.

This room is the domain of Dan Safley, head distiller, who has been with Newport Craft for three years.

Two copper and stainless-steel vessels are the stars here. One is a 300 gallon pot still, its distinguishing shape known as a “helmet,” used for making whiskey, bourbon and rum. And the other a German-made Christian Carl, its identifying shape known as a “column,” which is a 100 gallon hybrid still used for making vodka and gin. The different shapes and designs influence the flavors of the spirits being made.

The distilled whiskey spirits are emptied from the pot still into a container, where filtered water is added. Then, the contents go into a barrel. A typical bottle of Sea Fog Whiskey will stay in the barrel for 6-7 years. After it’s aged the appropriate amount of time, the barrel returns to Newport Craft, where the contents are bottled.

“Every batch we make we do in small quantities,” says Safley, noting that 80 percent of the whiskey flavor comes from the barrel. There are currently more than 700 barrels of aging spirits in Newport Craft’s warehouse. By 2025, Safley expects to be making 200 barrels a year of each spirit.

For vodka and gin, the process is similar but different. Vodka and gin share a base but become distinctive spirits once botanicals are added to the mix, giving gin its unique flavor. At Newport Craft, the gin is called White Squall, and the botanicals are formed of juniper, Szechuan peppercorn, lemongrass, elderberry, cardamom and cassia bark (not to be outdone by his brewing colleagues, Safley named all of those on the spot). After the addition of botanicals, gin goes back into the copper still for an additional distillation.

Like with beer, the process for making spirits is very technical, and really comes down to chemistry and the manipulation of flavor profiles.

There are six tanks in the distilling room: four fermenters, one mash-cooker and one cold liquor/hot liquor tank, “which just means water,” says Safley. Across the room, there is a grist mill, which is fed grain from the silo, and which feeds finely ground grain to the mashcooker.

“It took some time, but we have a really good team,” says Safley, who was often bantering with his brewing mates while walking through the brewhouse, “everyone is willing to help out each other.”

O’Donnell is proud of all Newport Craft has accomplished so far.

“Our distinctiveness lies in the unparalleled nature of our enterprise within the nation,” he says. “We possess the capability to manufacture almost any product, accommodate most events, and boast a facility nd team of a world-class caliber, situated in one of the most illustrious cities in the country.”

“Our identity transcends the conventional boundaries of a brewery, distillery, beverage manufacturer, taproom, or event space,” he continued. “We are a sustainably constructed platform, equipped with the infrastructure to scale and adapt to any envisaged future as a top 50 sized brewery and distillery in the country.”

RECENT AWARDS & DISTINCTIONS

- Sea Fog Single Malt Whiskey: 2023 – 90 rating from Whiskey Advocate; 2023 Gold – Ascot Awards; 2023 Silver – East Coast Craft Spirit Awards

- Sea Fog Rye Whiskey: 2023 – 90 rating from Whiskey Advocate; 2023 Gold – Ascot Awards; 2023 Silver – East Coast Craft Spirit Awards

- Thomas Tew Single Barrel Rum: 2023 Gold – East Coast Craft Spirit Awards

- Thomas Tew was the Official Rum of the NY Mets from 2021–2023

- Thomas Tew was the Official Rum of Boston Calling in 2022 and 2023

- Newport Craft was named 9th Best Rum Distillery in USA by USA Today in 2022

PRODUCT BREAKDOWN

SPIRITS

- White Squall: Vodka, Gin, Moonshine

- Thomas Tew Rum: Single Barrel, 10 Year, Coopers Blend, Spiced

- Sea Fog Whiskey: American Single Malt, Rye

- Coming Soon: Spiced Whiskey, Coffee Liquor, White Squall Blueberry, Bourbon

BEER

- Newport Craft core lineup: Rhode Trip (NE IPA), Rhode Rage (Double IPA), Rhode Runner (Craft Lager)

- Radiant Pig core lineup: Save The Robots (East Coast IPA), Double Save The Robots (Double IPA), Western Robot (West Coast IPA)

- Braven Brewing: Bushwick Pilsner

ALTERNATIVE BEVERAGES

- Clear Harbor Water Co. lineup: Water, Sparkling Hop Water, Sparkling Water, CBD Water (coming soon)

- Cider by the Sea (hard cider)